Contamination Control Products

For Process Rotating Equipment

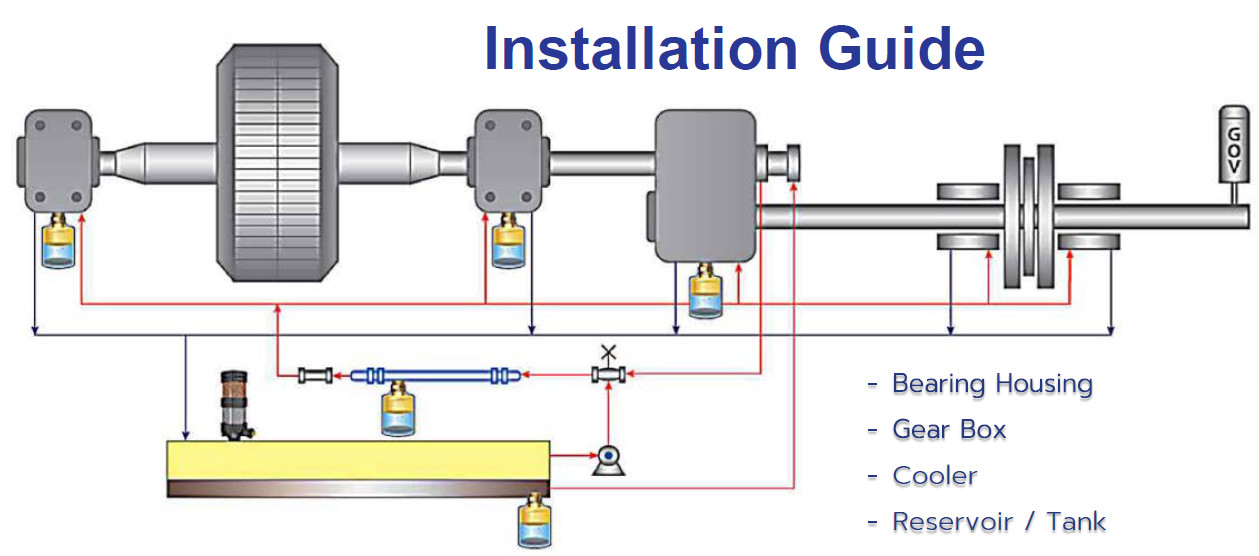

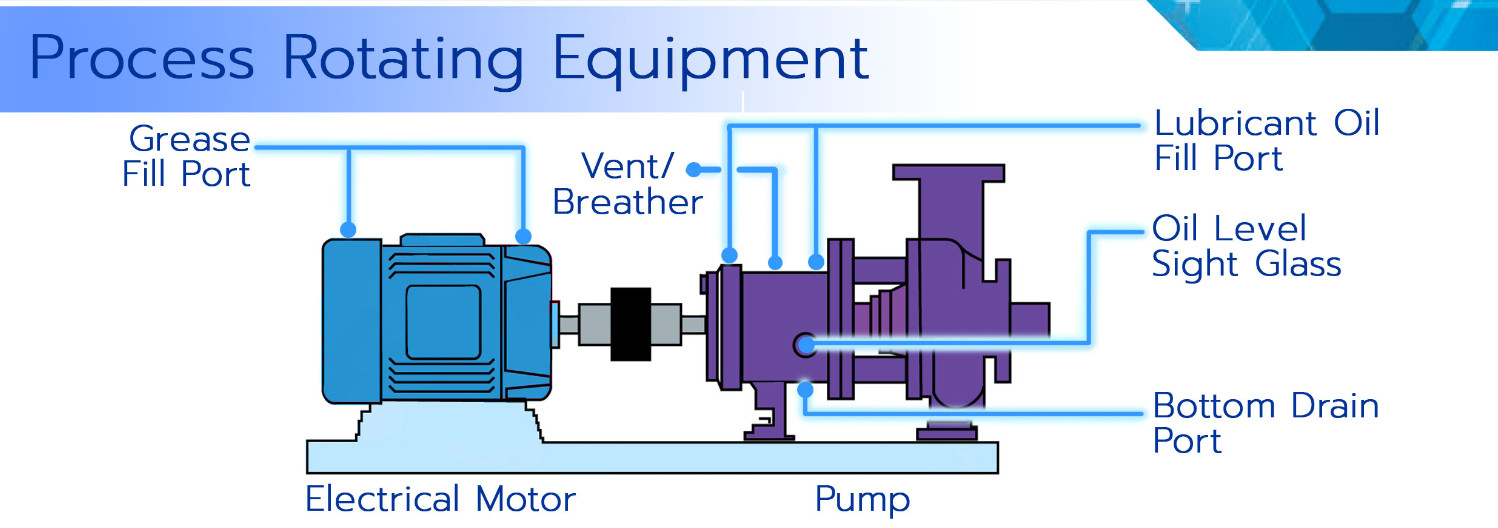

Process Rotating Equipment is assumed the common equipment likely pump, motor, fan, or components such as bearing and gear.

Equipment classification is used to identify the level of priority when fixing the machinery. Mostly, critical equipment using conventional lubrication methods, often known as "Oil sump" fails frequently due to poor lubrication condition and lead to many loses in the plant.

OilSafe - GreaseSafe

OIL SAFE - Excellent container for transfer lubricant oil from lube room to site.

1. 5 size available (1.5, 2, 3, 5 & 10 L)

2. 5 type of Lids for varies work

3. HDPE Material

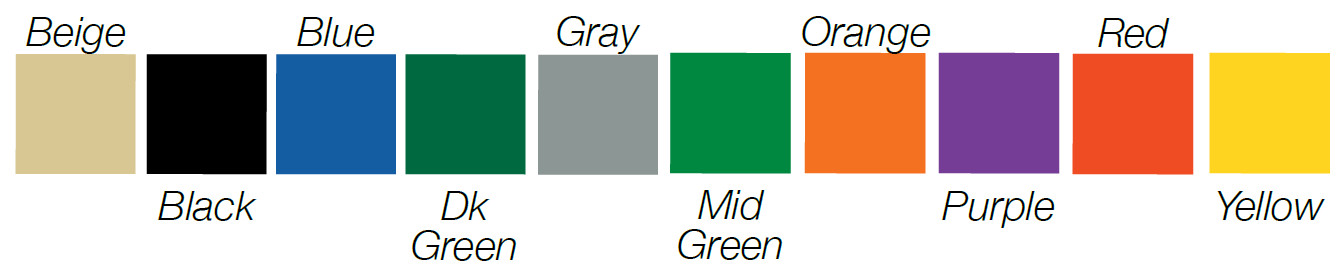

4. Color coding apply with 10 colors

5. Contamination control

6. Liquid spill protection

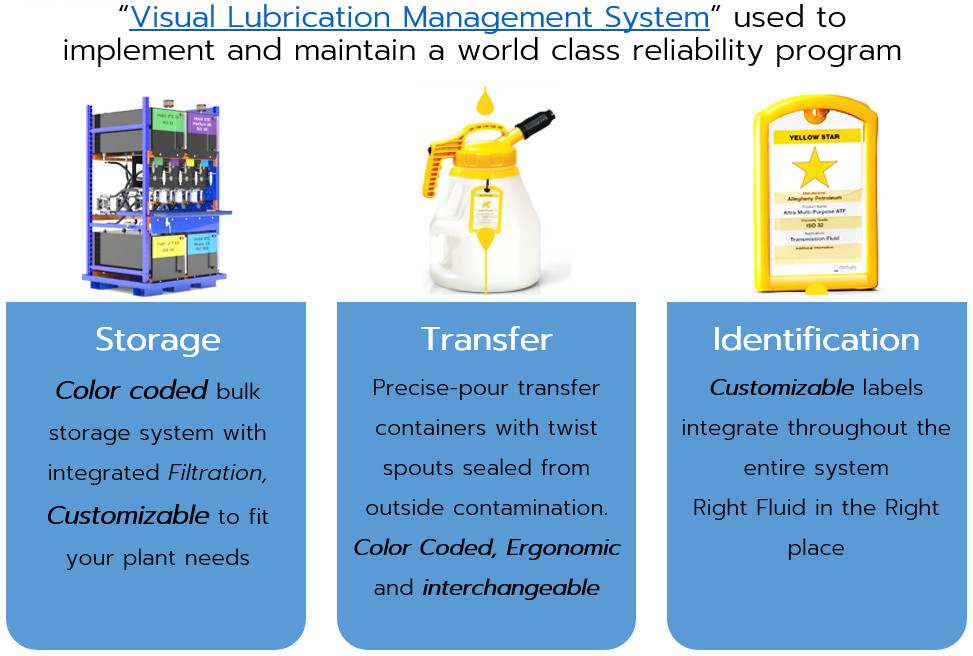

OIL SAFE Visual Lubrication System

By color-coding your lubricants and integrating with our OILSAFE identification products you'll prevent cross-contamination and misapplication of oils. With 5 different lid types designed to fit each of the 5 different drum sizes, you can mix and match the components to build heavy-duty durable containers that meet your oil transfer requirements.

Desiccant Air Breather For Prevent Moisture In Air

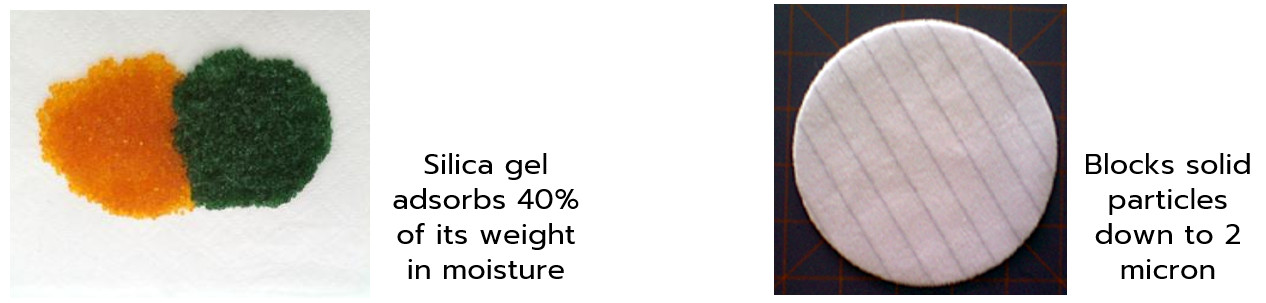

Whitmore®'s Desiccant Breather line, Air Sentry®, sets the standard for contamination control. These breathers have state-of-the-art features that reduce particulate and moisture contamination, keeping your equipment and fluids lasting longer. The innovative breather line integrates check valve technology in a desiccant breather and offers replacement cartridges, to significantly reduce maintenance costs. The clear view 360 degree design makes it easy to inspect the saturation of the color-changing silica gel from a distance. The inert silica gel turns from gold to dark green to visually indicate the adsorption of moisture and confirm the breather is getting the job done.

View & Drain Bottle

Features

+ Easy to monitor ingress of water into the used oil

+ Visual judgment of degradation status of used oil

+ Separation of free water from used oil and discharge

+ Quick judgment of sealing failure and crack

+ Removal of ferrous wear of the equipment

+ Integrated strong magnet inside

+ Prevents from breakage due by double protection housing

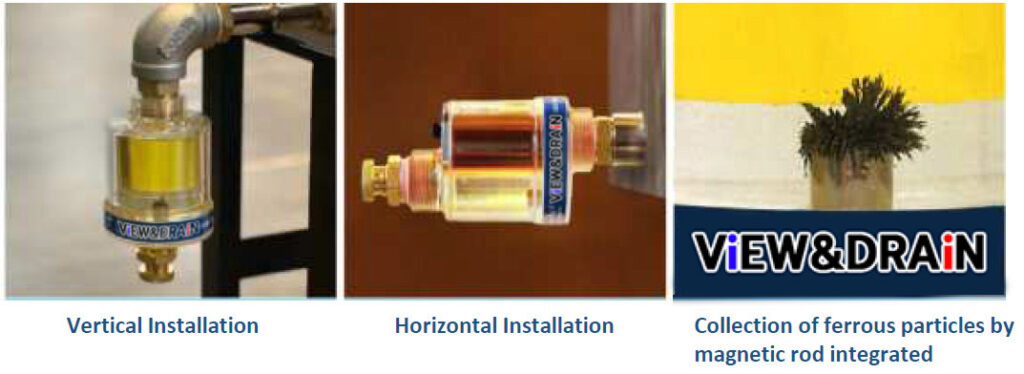

+ Can be installed in small spaces (horizontal & vertical installation)

Specifications

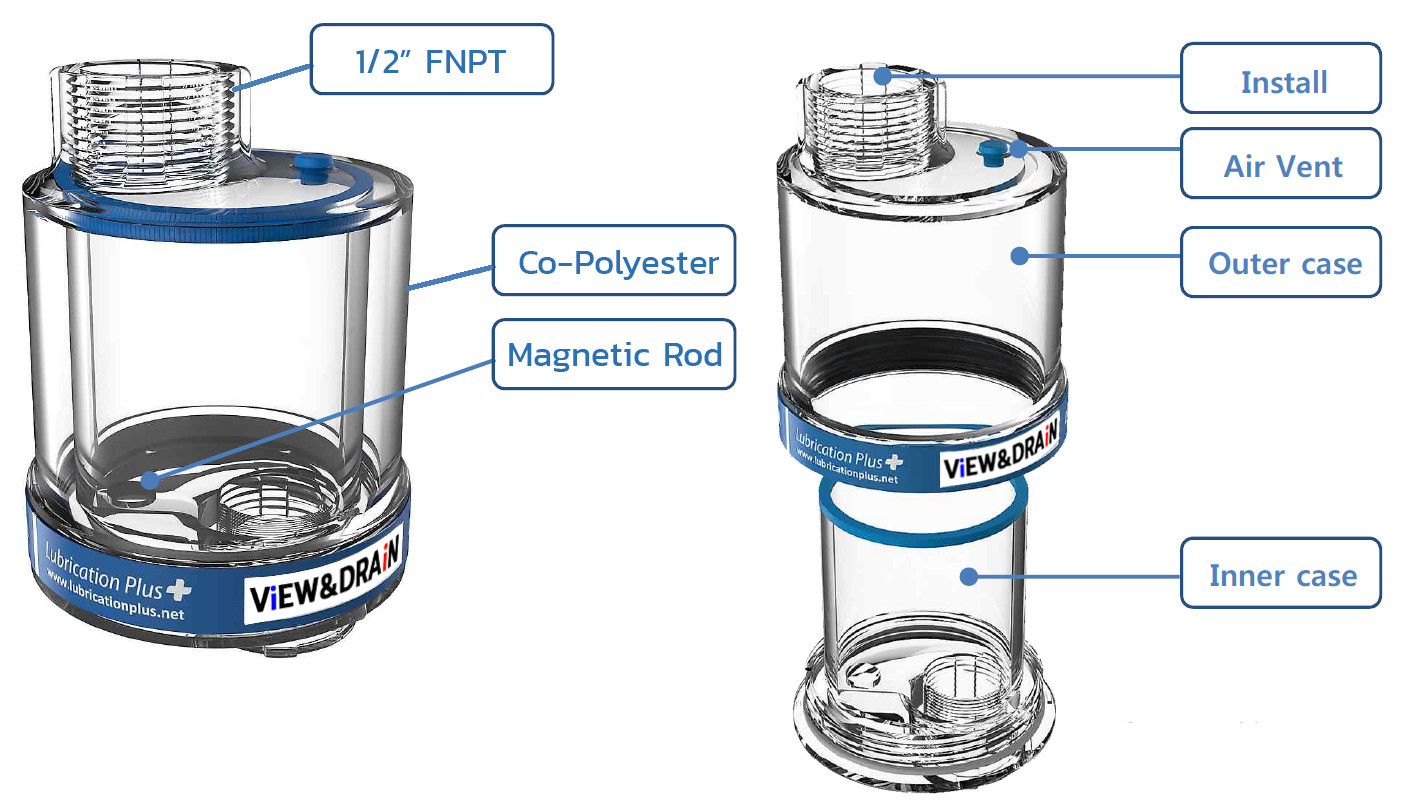

Item: CC1101

Part No.: CC1101

Connection: PT 1/2"

Dimension (D*H): 45*80 mm

Body Material: Co-Polyester

Composition: Double Housing, Air Vent Plug, Magnetic

Installation: Vertical or Horizontal

Working Temperature: -10 C to 90 C