FILTER CART FOR PARTICLE REMOVAL IN LUBE OIL

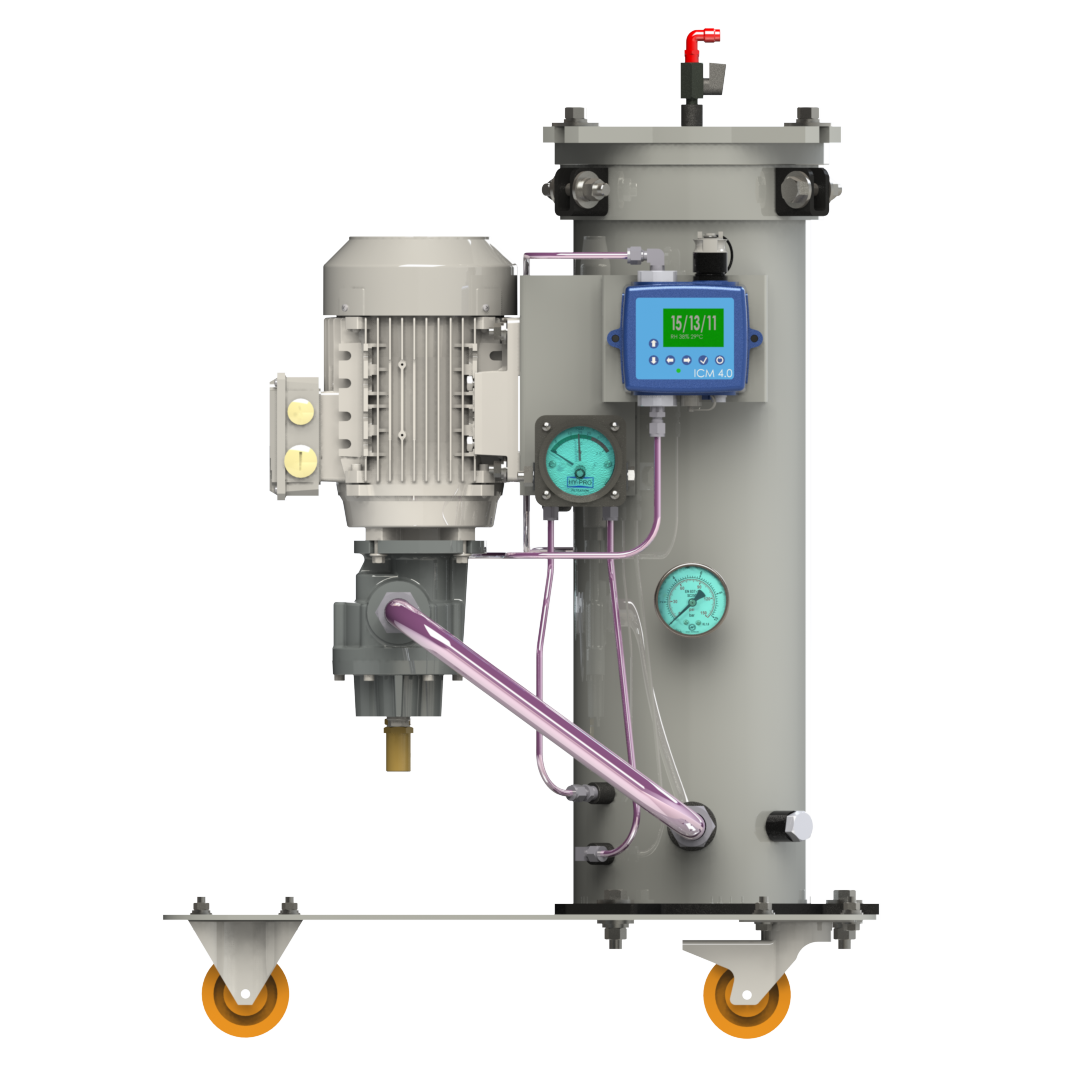

Model: FCL-ICM

Flow Rate: 35-300 lpm

Filter: HP-CC06L18-3MB

Viscosity: 32 - 1,000 cSt @40°C Dimensions (HxLxW): 95x75x50 cm

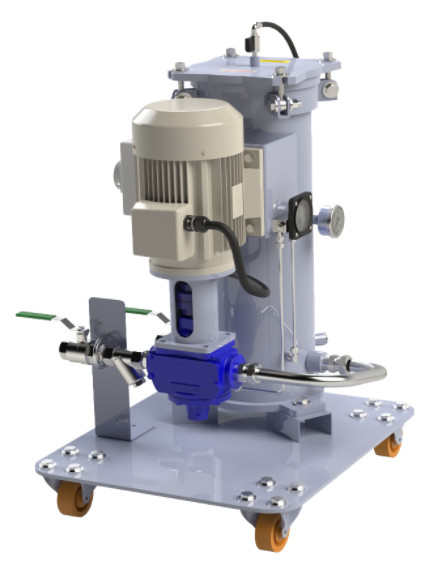

Model: LR70

Flow Rate: 70 lpm

Filter: HP-CC06L18-3MB

Weight: 85 kg

Dimensions (HxLxW): 95x75x50 cm

Model: LR40V

Flow Rate: 40 lpm

Filter: HP-CC06L18-3MB

Weight: 80 kg

Dimensions (HxLxW): 83x65x55 cm

Model: Compact Filtration Unit

Flow Rate: 25 lpm

Filter: HP-CC75L8-3MB

Weight: 21 kg

Dimensions (HxLxW): 54x54x31 cm

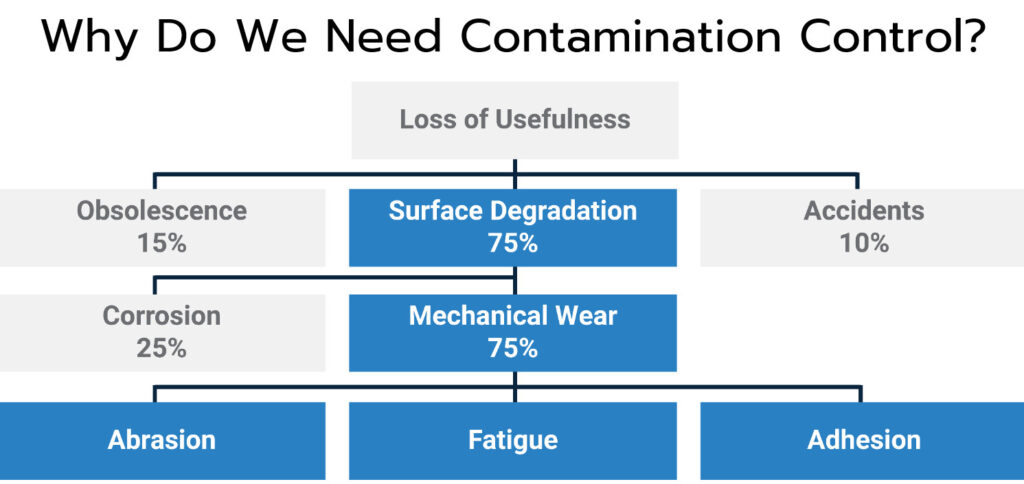

Machines requiring a lubricant film experience a wide range of failure opportunities. Typically, the most common is surface degradation due to a contaminant. There are several types of surface wear mechanisms with the majority due to a particle affecting the surface of a bearing, rolling element, gear face, or pump component.

Have a question?

Please feel free to let us know.

Our Full-Service Team Is Providing Technical Consults To Customers including Site surveys, Equipment Inspection, System Sizing & Budget estimates, Investment Justification, Installation, Maintenance Program, Trial Program, And On-site services.

GET YOUR FREE CONSULT NOW !!