SOLUBLE VARNISH REMOVAL "SVR"

Proven Solution for Preventing Lubricant Varnish

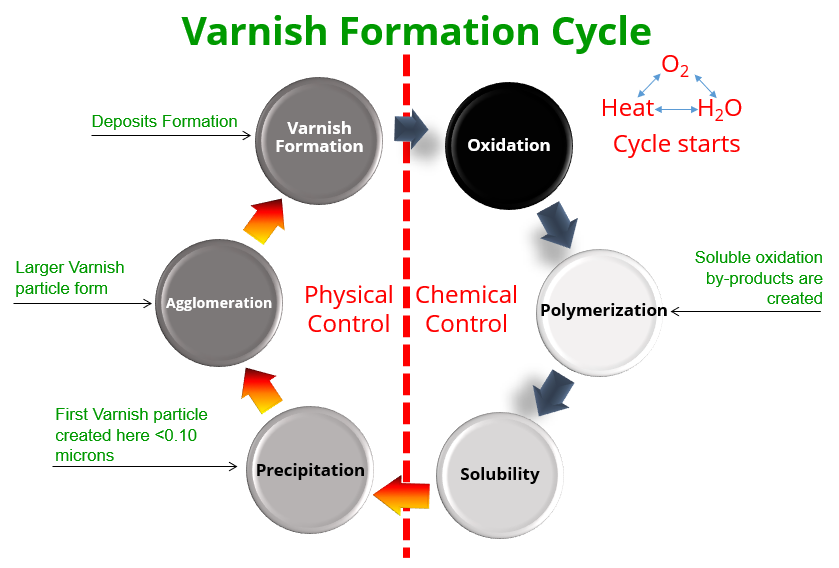

From the moment lubricants are put into service, they chemically breakdown. The primary pathway: oxidation.

Over time chemical breakdown products accumulate, saturating the lubricant with unwanted contamination, initiating lubricant failure. Left unmanaged, the formation of insoluble particles, deposits and varnish are inevitable.

This contamination, chemically attracted to mechanical surfaces, results in: mechanical failures and costly production losses. For too long this has been the status quo. It’s time to manage the unmanaged.

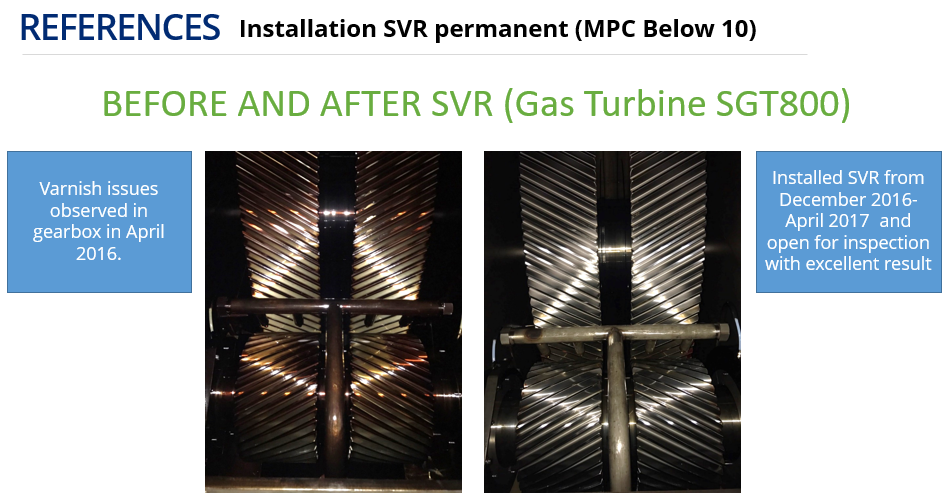

The problem with Gas Turbine machinery having varnish often arises due to issues in various system components.

Varnish is a substance that develops from the degradation of turbine oil or lubricating oil used in the Gas Turbine's system. Its altered structure forms varnish deposits that accumulate on internal surfaces of the machinery. Factors contributing to this include

1. high operational temperatures

2. oil oxidation

3. unfavorable environmental conditions

4. Reduced Efficiency

5. Abrasive Wear

Effectively addressing varnish deposit issues requires systematic maintenance and engineering-focused care to ensure continuous and efficient system operation.

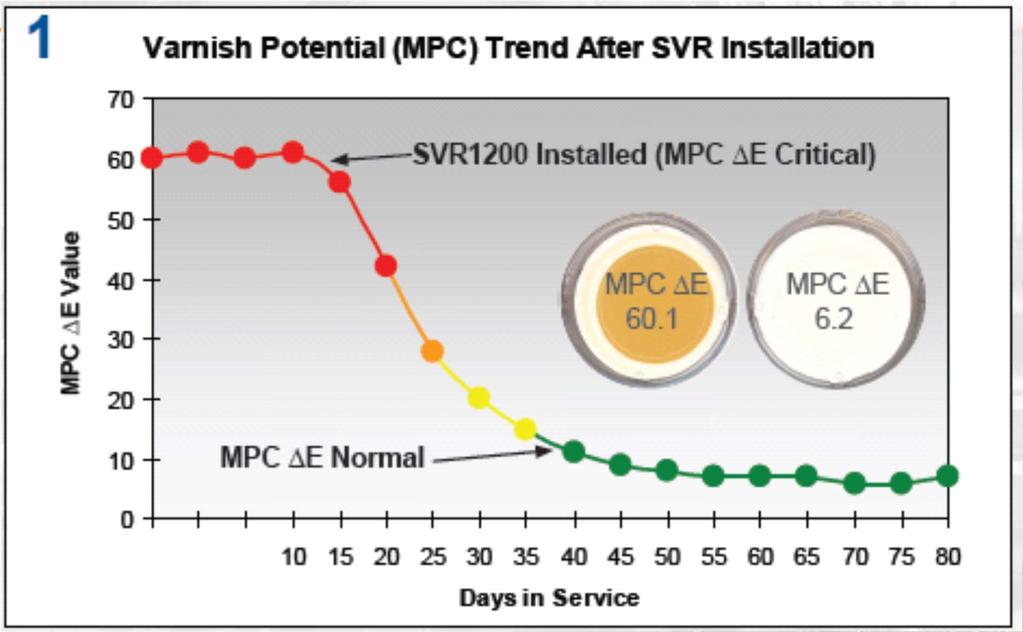

MPC varnish potential testing (ASTM D7843) is an essential analytical test to determine the propensity for a lubricant to form varnish deposits. With the probability of varnish-related failures reported to be as high as 100% (GE TIL 1528-3), monthly MPC testing is recommended for all critical turbine installations.

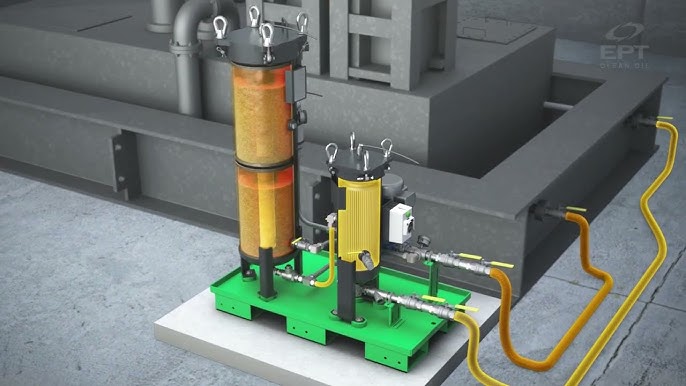

Best Practice is using the "SVR"

1. Reversing the chemical reaction of varnish deposit formation

2. Off-line SVR connects to main lube reservoir up to 8000 gal/30,000 liters

3. Oil is circulated through ICB vessel & post filter

4. Soluble oxidation byproducts removed by ICB cartridge

5. Oxidation byproduct level in oil drops below saturation point

6. Oil regains solubility

7. Insoluble oxidation byproducts are dissolved back into oil and removed by ICB cartridge

8. Oil regains solubility (oxides removed as created)Varnish is dissolved back into oil and removed by ICB cartridge

Features and Benefits

1. Removes and prevents all forms of varnish (solid and dissolved)

2. Removes dissolved breakdown molecules that are formed as part of standard equipment operation, preventing the varnish formation cycle from starting

3. Reverses the varnish formation cycle, restoring lubricant solvency and removing varnish deposits via chemical equilibrium

4. Prevents varnish related bearing and servo valve failures

5. Reduces MPC values and keeps them low

6. Manages the fluid chemistry, minimizing the impact of oxidation, decreasing anti-oxidant additive consumption rates and extending the lubricant life

7. Does not affect turbine oil additives

8. Creates a trouble-free operating environment with predictable outcomes and costs

9. Maintains oil condition standards required by ASTM D4378: Standard Practice for In-Service 10. Monitoring of Mineral Turbine Oils for Steam, Gas and Combined Cycle Turbines