The ThermoJet® Oil Purifier

Principal of Operation

The ThermoJet® works on the principal of air stripping. The use of air or nitrogen bubbled through contaminated liquids has long been used to remove contaminants. But the use of this technique was restricted because the volume of gas required was large due to limited mixing of the gas with the liquid. The unique technology embodied by the ThermoJet® makes air/gas stripping practical and efficient because of the mixing and intimate contact of the air/gas with the fluid being cleaned. In addition, the ThermoJet® utilizes the principal that the capacity of a gas to entrain moisture increases exponentially with temperature. For example, with a 55-degree Celsius increase in temperature, there is a 30-fold increase in the capacity of gas to hold moisture.

The THERMOJet® Oil Purifier not only removes free water it also removes emulsified and dissolved water meaning compressor, turbine lube oil and hydraulic systems can be kept water-free.

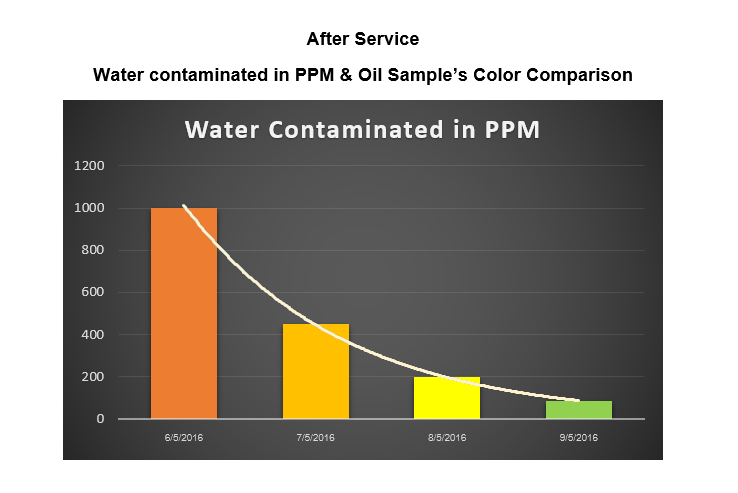

This results in improved reliability of machinery and also eliminates the need for frequent changes of lube oil. The THERMOJet® will take oil that contains 1000 PPM of water down to a total water content of less than 100 PPM within five passes of the oil through the unit. The THERMOJet® outperforms other equipment such as settling tanks, coalescing filters, and centrifuges.

The ThermoJet® Diagram

The ThermoJet® removes dissolved light hydrocarbon gases such as propane and H2S from industrial lubricants. In refineries and petrochemical plants an ideal application for the ThermoJet® is the removal of hydrogen sulfide from compressor seal oil. The ThermoJet® returns the viscosity of the lube oil and restores the oil flashpoint to like-new levels. No longer is there a need to dispose of gas-laden and sour lube oils; these oils can be purified and reused. Contaminants disposed of thru the flare system.